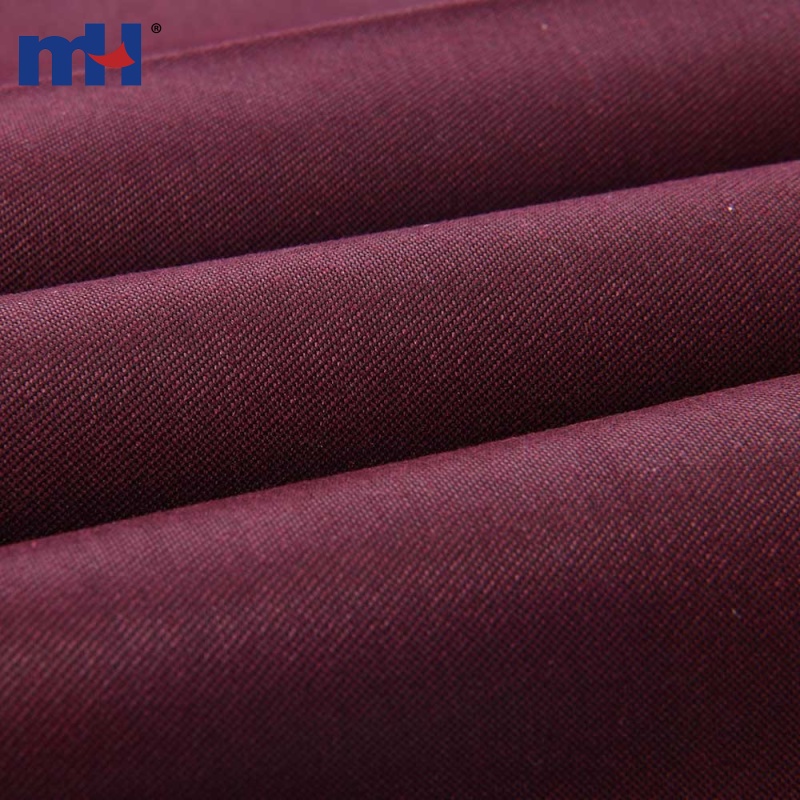

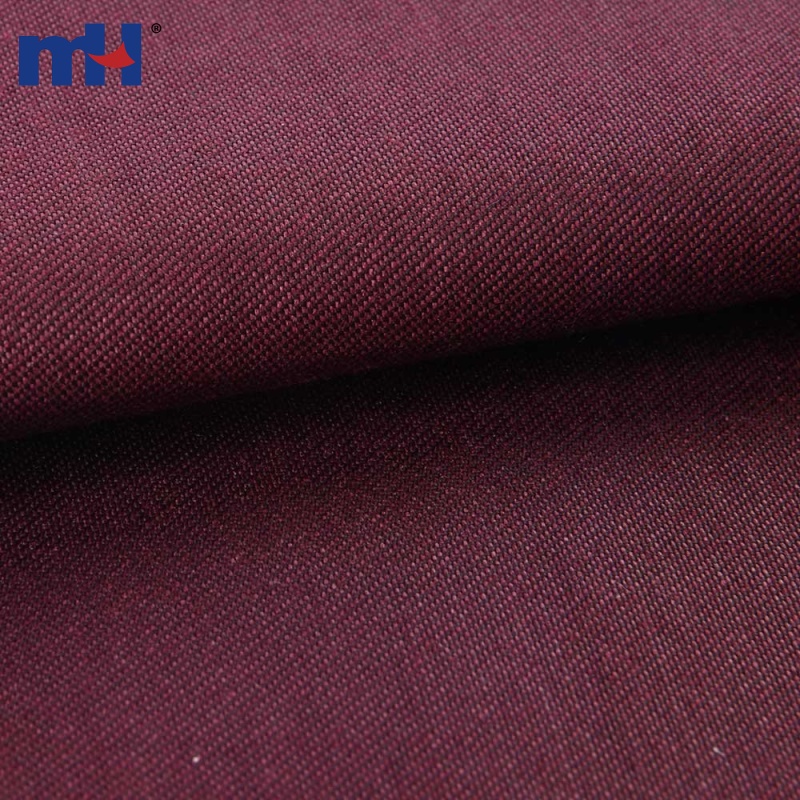

100% Polyester Imitation TR Fabric

100% Polyester Imitation TR Fabric Supplier and Exporter

- Model8152-0081

- Material: 90% Polyester 10%Rayon

- Warp and Weft Yarns: 90*74

- Yarn Count: [100D+100D*(100D+50S)]*(100D+32S+32S)

- Weight: 180g/㎡

- Width: 150cm

- Custom raw materials

- Custom yarn count

- Custom colors

- Custom packings

- Custom logo

Most samples are free, while a few may require a purchase; shipping costs are the responsibility of the recipient.

- Lead Time: 25-35 days

- Shipping: Sea freight, Railway freight, Air freight

- Payment: T/T, L/C ...

- WhatsApp: +8615658271710

Email: sales@mhfabric.com

| Product Name | 100% Polyester Imitation TR Fabric |

| Material | 100% Polyester |

| Technique | Weave |

| Process Treatment | Calendering |

| Warp and Weft Yarns | 100*68 |

| Yarn Count | 150D*30S |

| Weight | 135g/㎡ |

| Width | 57"-58" |

| Sample Card | Available |

| Color Card | Available(Clik to Download the PDF file) |

| Feature |

100% polyester TR (Terylene Rayon) imitation fabric is a type of textile that is designed to mimic the appearance the texture of TR fabric. Cost-Effective: Polyester fabrics are typically more affordable than their natural counterparts. Durability: Polyester is known for its durability and resistance to wrinkles, which makes TR imitation fabric a low-maintenance option for clothing and home textiles. |

| Usage | The 100% Polyester Imitation TR Fabric is mainly used as garment fabric, especially for trousers, workwear, uniform, etc. |

| Packing | According to the customer's requirement |

| Custom Service | Material, Denisty, Denier, Color, Pattern, Packing, Brand, etc. |

TR Fabric Color Card (Clik the image below to download the color card PDF file)

TR Fabric Sample Card

TR Fabric Packing

TR Fabric Factory

Weaving

MH's products are made by China’s advanced air jet non-shuttle looms, which not only improve production efficiency, but cut cost and save energy as well. Besides, finished fabric has few thread residues, and are tidy, flat.

Dyeing

The grey fabric are dyed by automatic temperature control systems and high-temperature high-pressure dyeing equipments. Finished fabric have even surface, bright color and excellent color fastness, and the color difference meet Europe standard.

High temperature setting

Imported setting machines help fabrics dry quickly, keeping them flat, even, and stable in width.

Fabric inspection

During producing, inspection process is in each process, from raw yarn, grey fabric, to dyed and finished fabric, only the qualified fabric which meet Europe standard can be shipped out to customers.

About Ningbo MH

Ningbo MH was established in 1999, and specialized in garment accessories and tailoring materials.

At present, MH owns nine factories located in 3 industry zones, with a 382,000㎡ plant area and 1900 workers, producing polyester sewing thread, embroidery thread, lace and embroidery, ribbon tape.

MH also set up long-term cooperation with 1500 manufacturers for 10000 different kinds of tailor's material and fabric.

MH Company ISO Certificates

MH has certificates of ISO 9001:2015, ISO14001:2015, ISO45001:2018