Foil-Printed Velvet Upholstery Fabric

Foil-Printed Velvet Upholstery Fabric Made in China

- Model20NW-8058

- Material: 100% polyester, with the fabric made from 75D + 50D polyester fibers.

- Weight: The base fabric weighs 110g, the composite double-sided velvet weighs 80g, and the total weight is 190g/m².

- Width: 145 cm.

- Custom raw materials

- Custom yarn count

- Custom colors

- Custom packings

- Custom logo

Most samples are free, while a few may require a purchase; shipping costs are the responsibility of the recipient.

- Lead Time: 25-35 days

- Shipping: Sea freight, Railway freight, Air freight

- Payment: T/T, L/C ...

- WhatsApp: +8615658271710

Email: sales@mhfabric.com

Material Composition: 100% polyester, with the fabric made from 75D + 50D polyester fibers.

Weight: The base fabric weighs 110g, the composite double-sided velvet weighs 80g, and the total weight is 190g/m².

Width: 145 cm.

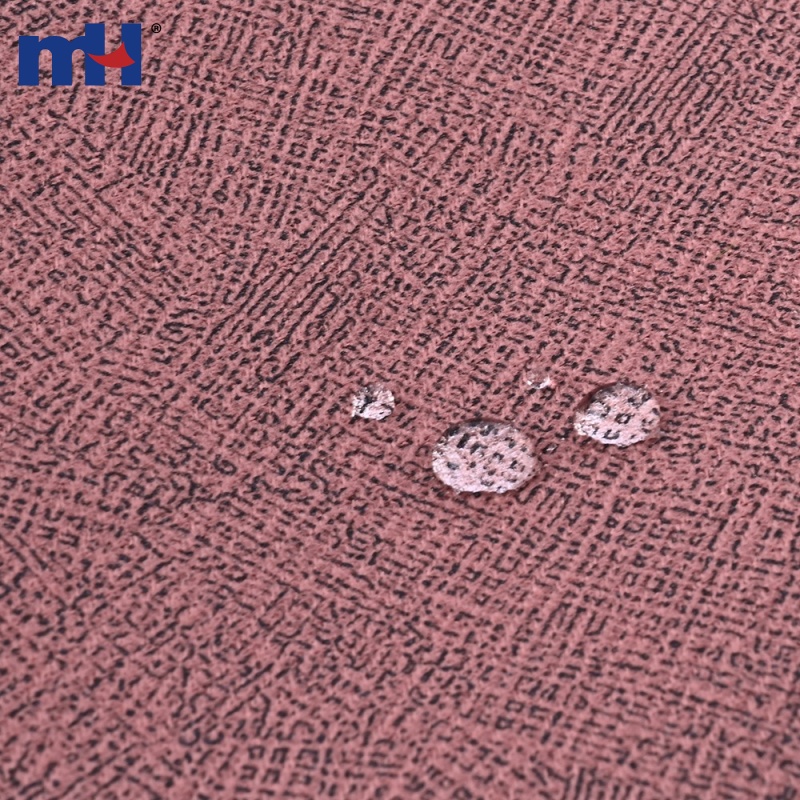

Surface Treatment: Foil-printing process, giving it the texture of faux cotton velvet.

Foil stamping is a common decorative surface treatment technique, primarily used to apply metallic designs or text onto materials such as fabric, paper, leather, and more. This process gives the product a shiny gold or other metallic-colored finish, enhancing its visual appeal and texture. The specific steps involved in the foil stamping process are as follows:

-

Foil Preparation: Foil is a thin film with a metallic sheen. Common colors include gold, silver, and copper, but other colors and special effects are also available.

-

Mold Preparation: A metal mold is created based on the design, with the pattern or text engraved on it.

-

Heat Pressing: During the stamping process, a foil stamping machine uses high heat to press the metal mold onto the material's surface. The combination of heat and pressure allows the metallic layer of the foil to bond with the material, transferring the design or text onto the surface.

-

Excess Foil Removal: After pressing, the excess foil is peeled away, leaving behind the desired metallic design or text.

This method is widely used to create high-end visual effects on various products, adding a luxurious and refined finish.

Key Features: Laminated with adhesive backing, providing waterproof functionality. It is durable and easy to clean.

Applications: Ideal for sofa upholstery, adding a luxurious visual appeal and a comfortable touch to home furnishings. It is both practical with its waterproof feature and aesthetically versatile, suitable for various interior design styles.

Other Fabric Materials

MH cooperates with 3000+ factories, supplying poplin, taffeta fabric, TR fabric, TC fabric, minimatt fabric, satin fabric, polyester pongee fabric, etc.

We can also supply fabrics and accessories according to your end usage, such as T-shirt, shirt, suiting, workwear, school unform, sportswear, curtain, mattress, sofa, outdoor gear, bag and luggage, etc.

ONE-STOP Services cater to all your needs!

About Ningbo MH

Ningbo MH was established in 1999, and specialized in garment accessories and tailoring materials.

At present, MH owns nine factories located in 3 industry zones, with a 382,000㎡ plant area and 1900 workers, producing polyester sewing thread, embroidery thread, lace and embroidery, ribbon & tape.

MH also set up long-term cooperation with 1500 manufacturers for 10000 different kinds of tailor's material and fabric.

MH Company ISO Certificates

MH has certificates of ISO 9001:2015, ISO14001:2015, ISO45001:2018