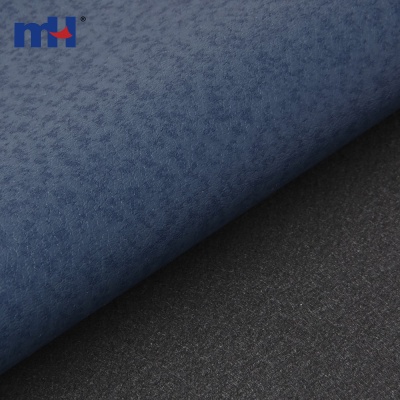

Pearlized Leather Lining for Shoes

0.55mm 54 Inches Pearlized Leather Lining for Shoes

- Model24nw-4013

- Material: PU+Spunwoven Lining

- Thickness: 0.55mm

- Widths: 54 inches

- Technique: Pearlized surface

- Lead Time: 25-35 days

- Shipping: Sea freight, Railway freight, Air freight

- Payment: T/T, L/C ...

- WhatsApp: +8615658271710

Email: sales@mhfabric.com

Material: PU+Spunwoven Lining

Thickness: 0.55mm

Widths: 54 inches

Technique: Pearlized surface

Features of Pearlized Leather Lining

- Good flexibility: The PU material itself has good flexibility, enabling the PU shoe lining leather to adapt to the bending and movement of the feet. It can bend with the movement of the feet without breaking easily, providing a comfortable wearing experience.

- Lightweight: Compared with natural leather, PU shoe lining leather has a lower density and is lighter in weight. This helps to reduce the overall weight of the shoes, making the wearer feel more relaxed, especially suitable for sports shoes and other types of shoes that require lightweight performance.

- Price advantage: Its production cost is relatively low, and the price is more affordable than natural leather shoe lining leather. This makes it widely used in the mid - to - low - end footwear market, meeting the needs of different consumers.

- Easy to process: PU shoe lining leather can be decorated through various processing methods such as dyeing, printing, and embossing. For example, it can be easily dyed into various bright colors, or the texture of natural leather can be simulated through the embossing process, increasing its aesthetic appeal.

- Improved breathability products: Although the breathability of traditional PU shoe lining leather is not as good as that of natural leather, through some technological improvements, such as using special breathable coatings or adding breathable components to the PU material, its breathability has been improved to a certain extent, which can meet the basic needs of daily wear.

Manufacturing Process of Pearlized Leather Lining for Shoes

Base Fabric Preparation

-

Base fabric selection: Non-woven fabric is a common choice for base fabrics, made of oriented or random fibers with moisture-proof, breathable, and flexible properties. Knitted fabric is also widely used, offering good elasticity and softness. The choice of base fabric depends on the specific use and performance needs of the shoe lining leather. For instance, sports shoe linings may use knitted fabric for its better elasticity.

-

Base fabric pretreatment: The base fabric must be cleaned and pretreated to ensure a smooth, impurity-free surface, which helps with PU coating adhesion. This typically involves desizing and degreasing. Desizing removes the sizing agent used during weaving, while degreasing eliminates grease and other impurities. For example, cleaning the base fabric with an alkaline detergent at the right temperature and time achieves optimal results.

PU Coating or Impregnation

Coating method:

-

Material preparation: Mix PU resin, solvents (e.g., dimethylformamide, toluene), pigments, and additives (e.g., leveling and antifoaming agents) to prepare a coating slurry. The PU resin determines the basic performance of the shoe lining leather; solvents adjust slurry viscosity for easier coating; pigments add color; and additives improve coating quality. Typically, the slurry contains 60-80% PU resin, 1-5% pigment, and 0.1-1% additives as needed.

-

Coating method: The PU coating slurry is applied to the base fabric using methods like knife-coating, roll-coating, or spraying. Knife-coating controls thickness and works for thicker shoe linings; roll-coating is efficient and uniform; spraying creates finer coatings. On automated production lines, roll-coating is common, allowing thickness control between 0.1-0.5mm by adjusting roller pressure and speed.

-

Drying and curing: After coating, the base fabric is dried and cured to remove the solvent and harden the PU resin. Drying temperature and time depend on the resin type and coating thickness, typically 80-120°C for 3-10 minutes, forming a durable PU coating film.

Impregnation method:

-

Preparation of impregnation solution: Dissolve PU resin in a suitable solvent to prepare the impregnation solution. Adjust the concentration based on the desired thickness and performance of the PU layer. For thinner PU shoe lining leather, the concentration is typically 30-50%.

-

Impregnation process: Immerse the base fabric in the PU solution to allow the resin to penetrate the fibers. The absorption can be controlled using equipment like squeeze rollers. For example, the liquid absorption rate can be maintained at 100-200%.

-

Drying and curing: After impregnation, dry and cure the fabric at higher temperatures (100-140°C) for 5-15 minutes. This cures the PU resin and forms a durable PU shoe lining leather with the desired thickness and strength.

Post - treatment

-

Embossing treatment: To simulate the texture of natural leather or create unique patterns, emboss the dried and cured PU shoe lining leather. Using an embossing machine at 100–150°C and 5–15MPa, form the desired pattern on the surface. Popular textures like crocodile or litchi patterns can enhance the aesthetic appeal of the leather.

-

Surface treatment: Improve the wear and stain resistance of PU shoe lining leather with surface treatments. Apply a thin layer of wear-resistant or stain-resistant coating. Wear-resistant coatings may include polyurethane microspheres, while stain-resistant coatings often contain fluorocarbons to make the leather easier to clean and extend its lifespan.