Scuba Fabrics

95% Polyester 5% Spandex Scuba Fabrics Wholesale

- Material: 95% Polyester 5% Spandex

- Yarn Count: 75D/36F DTY+30D spandex

- Weight: 285gsm

- Width: 160cm

- Packing: 2kg/roll

- Custom raw materials

- Custom yarn count

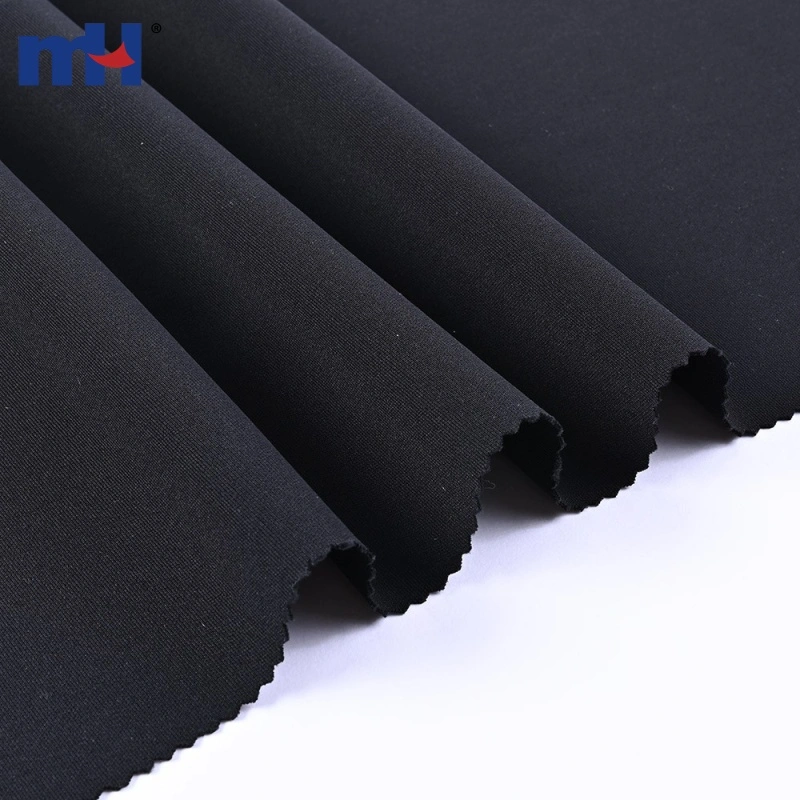

- Custom colors

- Custom packings

- Custom logo

Most samples are free, while a few may require a purchase; shipping costs are the responsibility of the recipient.

- Lead Time: 25-35 days

- Shipping: Sea freight, Railway freight, Air freight

- Payment: T/T, L/C ...

- WhatsApp: +8615658271710

Email: sales@mhfabric.com

Material: 95% Polyester 5% Spandex

Yarn Specification: 75D/36F DTY+30D spandex

- 75D indicates the denier of the yarn (the weight of 9000 meters of yarn is 75 grams.

- 36F indicates that the yarn is made up of 36 filaments.

- DTY (Draw Textured Yarn) provides good elasticity and softness.

Weight: 285gsm

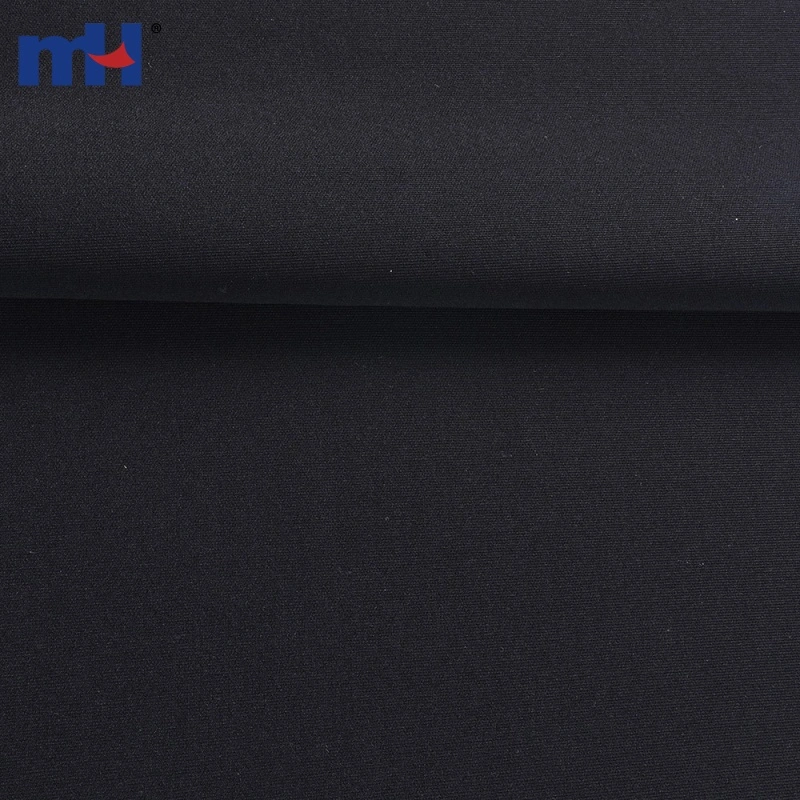

Width: 160cm

Packing: 2kg/roll

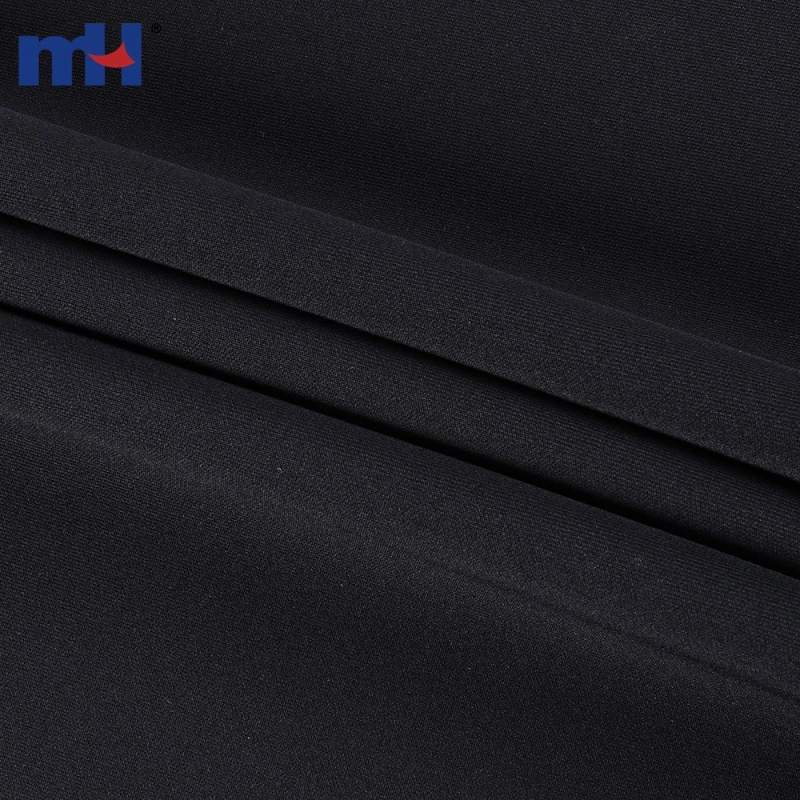

Features: Scuba is the fashion variety of the well known Neoprene material (also known as Chloroprene rubber). A double knit fabric that is normally a poly which has been mixed with Lycra or Spandex. It has a very smooth texture and a fine gauge thread. Scuba fabric is very springy.

- Material Composition: The Scuba Fabrics are made from 95% polyester and 5% spandex (elastane), providing a balance of strength and stretchability.

- Yarn Specification:

- Polyester: 75D/36F DTY (Draw Textured Yarn), offering a soft texture and good elasticity.

- Spandex: 30D, adding stretch and flexibility to the fabric.

- Weight: 285 grams per square meter (g/m²), giving the Scuba Fabric a substantial feel suitable for heavier applications.

- Width: 160 cm effective width, making Scuba Fabric versatile for various applications.

- Elasticity: The inclusion of spandex provides excellent stretch and recovery, ensuring comfort and fit.

- Durability: The polyester component offers durability and resistance to wear and tear.

- Wrinkle Resistance: The Scuba Fabric is resistant to wrinkles, maintaining a smooth appearance.

Applications:

- Activewear: Scuba Fabrics are Ideal for sportswear, yoga pants, leggings, and gym clothing due to its stretchability and comfort.

- Fashion Apparel: Scuba Fabrics are Suitable for making fitted garments such as dresses, skirts, tops, and pants, providing both style and comfort.

- Undergarments: Scuba Fabrics are perfect for making undergarments and lingerie, offering a close fit and comfort.

- Swimwear: Scuba Fabrics can be used for swimwear due to its stretch and quick-drying properties.

- Casual Wear: Scuba Fabrics are suitable for casual wear like T-shirts, hoodies, and sweatpants, offering comfort and flexibility.

- Performance Wear: Scuba Fabrics are ideal for performance wear that requires a snug fit and freedom of movement.

- Dancewear: Scuba Fabrics are excellent for dance costumes and athletic uniforms that require elasticity and durability.

This polyester/spandex blend Scuba Fabric combines the durability and resilience of polyester with the flexibility and stretch of spandex, making it suitable for a wide range of applications where comfort and fit are essential.

-

Direct-to-Client Services

Direct-to-Client Services -

Prompt Response without Time Zone Delays

Prompt Response without Time Zone Delays -

Effective Communication in Local Language

Effective Communication in Local Language

Other Fabric Materials

MH cooperates with 3000+ factories, supplying poplin, taffeta fabric, TR fabric, TC fabric, minimatt fabric, satin fabric, polyester pongee fabric, etc.

We can also supply fabrics and accessories according to your end usage, such as T-shirt, shirt, suiting, workwear, school unform, sportswear, curtain, mattress, sofa, outdoor gear, bag and luggage, etc.

ONE-STOP Services cater to all your needs!

About Ningbo MH

Ningbo MH was established in 1999, and specialized in garment accessories and tailoring materials.

At present, MH owns nine factories located in 3 industry zones, with a 382,000㎡ plant area and 1900 workers, producing polyester sewing thread, embroidery thread, lace and embroidery, ribbon & tape.

MH also set up long-term cooperation with 1500 manufacturers for 10000 different kinds of tailor's material and fabric.

MH Company ISO Certificates

MH has certificates of ISO 9001:2015, ISO14001:2015, ISO45001:2018